MULTI-MATERIAL PERSONAL PROTECTIVE EQUIPMENT

Our customer, an innovative international manufacturer of certified and high performance personal protective equipment.

1. THE NEED

- Achieve stability in production for its certified products complying to a variety of worldwide standards

- Produce highly aesthetics products featuring several delicate mechanisms made of engineering resins

- Onsite molding

2. THE SOLUTION

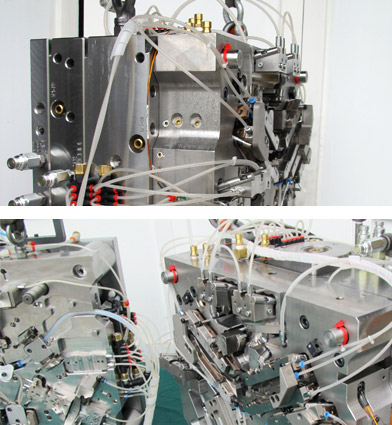

- Implement a fully automated production cell

- Design and manufacture multi-material plastic injection family molds

- With only 1 mold: molding of a 13 parts assembly at each cycle

3. TECHNICAL SPECIFICATIONS

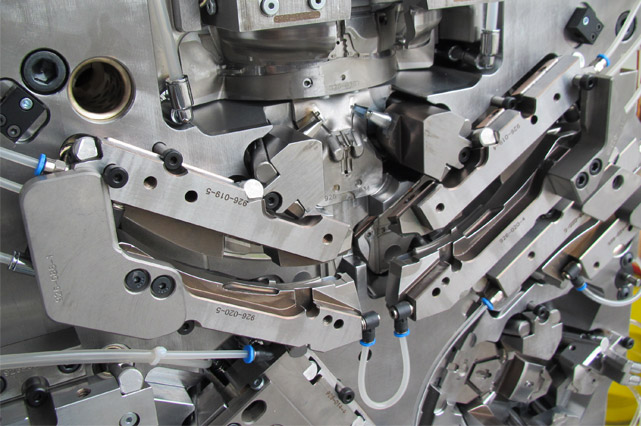

- Complex family molds in 50RC stainless steel

- 35 mobile inserts in a total of 53 molding inserts

- Perfect flow balancing with the use of hydraulic sequential valve gating

- In-mold assembly

- Robot automation and turnkey integration

4. THE BENEFITS

- Only 1 mold for each size of the product: we made it possible with the simultaneous molding of all 13 parts

- Production stability

- Optimized In-house multi-material molding station for just-in-time production

- Reduced overall production costs and improved productivity

- Quick ROI